EBNER | Applications | Automotive Industry

Applications for the automotive industry.

The automotive industry demands the highest temperature uniformity, reproducibility and reliability from a heat treatment facility. The standards specified within the industry, such as CQI-9 (AIAG), must also be met.

In addition to specifications for maintaining and operating furnaces, these standards focus on the following elements:

Thermocouples

Thermocouples must be calibrated before being used for the first time. The specified accuracy requirements and application criteria such as duration of use and frequency of use must be complied with for the relevant application (as control thermocouple, SAT thermocouple, TUS thermocouple).

Instrumentation and instrument testing

Instrumentation (temperature measuring and control systems) must be calibrated at regular intervals. The minimum accuracy must be maintained.

SAT (System Accuracy Test)

The complete measuring system of the temperature control system must be tested at specified intervals using a reference measurement. The measurement is performed using an SAT thermocouple and a suitable measuring instrument.

TUS (Temperature Uniformity Survey)

The temperature uniformity within a furnace qualified for CQI-9 must be proven at specified intervals.

All tests and surveys must be documented and traceability ensured.

EBNER meets or exceeds these quality criteria with its heat treatment facilities for dominant materials, such as aluminum in the aerospace industry and steel and aluminum in the automotive industry.

EBNER is also the right partner should an older model of furnace require an upgrade to meet automotive industry specifications. We would be pleased to assess your furnace facility and compile an upgrade package for the mechanical components, instrumentation and control system, including all documentation, installation and commissioning.

Regardless of whether material needs to be processed in coil-form, as a continuous strip or in plate-form, EBNER can supply a furnace facility tailored to each customer’s specific needs.

NEW in the EBNER product portfolio

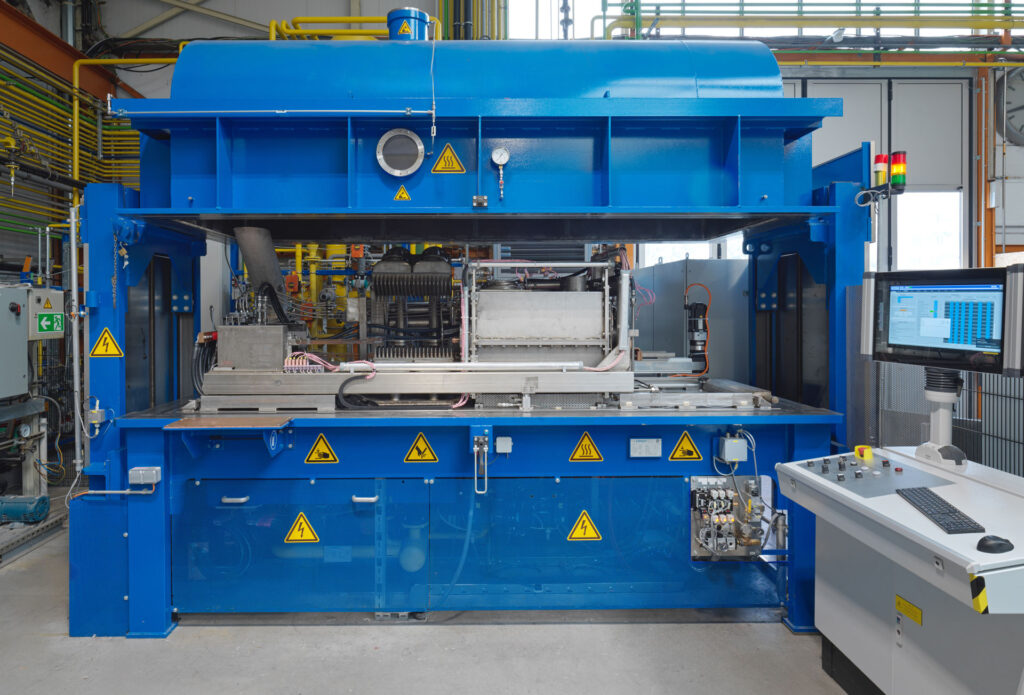

SIMCAL: Annealing simulator for continuous heat treatment facilities

EBNER offers SIMCAL annealing simulators as a complete system for your R&D center, research institute, etc. or as “Simulation as a Service”. As part of our service offer, you can use the SIMCAL for your test annealing at our in-house Tech Center in Leonding/Austria.