EBNER | Sustainability

The resolute pursuit of sustainability in production and the environment.

EBNER takes environmental responsibility very seriously. To us, “economy” and “ecology” are not opposites. As a globally-active family-owned company we constantly take an environmentally-aware approach, setting standards for eco-friendly production.

Customers place their trust in EBNER, not just because we are the world market leader for heat treatment furnace facilities, but because we are pioneers in the field of environmental protection.

E3 - Energy, Environment & (R)Evolution

EBNER is committed to sustainable production by developing facilities with outstanding energy efficiency and a strong focus on environmental responsibility. Through continuous innovation—such as energy recovery systems, lightweight workbases, and combustion air preheating using large recuperators—EBNER has significantly enhanced the energy performance of its technologies.

Customer comparisons consistently show a measurable advantage in energy consumption over competitors. This success is driven by the three pillars of the E³ concept: (R)Evoltuion, Environment, and Energy.

(R)evolution reflects our growth and integration of sustainability into all aspects of our business. Through strong governance, innovation, and employee engagement, we promote equal opportunities for personal and professional development. Environment focuses on reducing our ecological footprint by improving waste management, recycling, and emissions through advanced technologies. Energy drives our transition to renewable solutions, including new burner technologies, to enhance efficiency and support our customers in achieving their sustainability goals.

Built for Tomorrow: E³ Technology in EBNER facilites

Within the framework of sustainable production, EBNER focuses on the environment and has developed facilities, combustion technologies and digital solutions with an exceptional degree of energy efficiency and low emissions. This is not only a direct financial benefit for our customers, but also a step towards a more sustainable industry. With every kilowatt-hour of energy that is saved, and every reduction in emissions, EBNER proves that efficiency and sustainability can go hand in hand.

(R)Evolution

(R)EVOLUTION focuses on how we adapt and grow as a company, ensuring that sustainability is woven into everything we do.

With VISUALFURNACE 8, EBNER sets new digitalization standards. This modular .NET-based process control system supports hybrid networking and seamless integration with MES, PM, and ERP systems. Smart extensions like ATMOSPHEREperfect and MAINTENANCEperfect modules enhance efficiency, safety, and sustainability. Even existing systems can be upgraded to meet the latest standards. EBNER’s digital solutions turn sustainability into a competitive advantage through energy savings and intelligent process optimization.

With VISUALFURNACE 8, EBNER sets new digitalization standards. This modular .NET-based process control system supports hybrid networking and seamless integration with MES, PM, and ERP systems. Smart extensions like ATMOSPHEREperfect and MAINTENANCEperfect modules enhance efficiency, safety, and sustainability. Even existing systems can be upgraded to meet the latest standards. EBNER’s digital solutions turn sustainability into a competitive advantage through energy savings and intelligent process optimization.

Digitalization at EBNER includes the seamless integration of systems from the control level (PLC) via SCADA up to MES and ERP systems. This vertical networking enables the most efficient operation of the systems, as processes can be precisely controlled and resources optimally used. An example of this is the ATMOSPHEREperfect software module, which can save up to 20 % energy and hydrogen consumption through intelligent control.

Horizontal networking between systems enables in-line process control, predictive maintenance, digital shop floor management, and real-time energy monitoring. Tools like customizable energy dashboards and backup solutions ensure transparency and support continuous optimization.

In response to rising energy costs and the push for digitalization, EBNER developed the ATMOSPHEREperfect software module for HICON/H₂® bell annealers. This intelligent system uses real-time data and advanced algorithms to automatically regulate hydrogen flow, reducing energy and hydrogen consumption by up to 20 % without compromising product quality. Integrated into the VISUALFURNACES platform, it improves process stability, supports decarbonization, and strengthens the steel industry’s competitiveness through digital transformation and sustainability.

Energy savings

ECOMODE and TREATperfect are advanced tools designed to reduce energy consumption in heat treatment. ECOMODE optimizes fan and blower speeds, and also adjusts annealing times for maximum efficiency. TREATperfect enhances this with intelligent, real-time control and predictive planning – minimizing energy use, emissions, and material waste. Together, they improve furnace performance, increase throughput, and support sustainable, cost-effective manufacturing—even in retrofitted systems.

Energy savings

Energy

The ENERGY aspect of our E3 is dedicated to reducing energy consumption, enhancing efficiency, and leveraging innovative technologies to create more sustainable production processes.

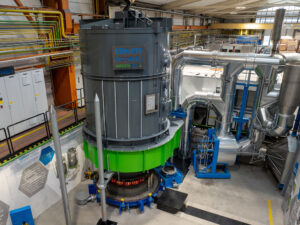

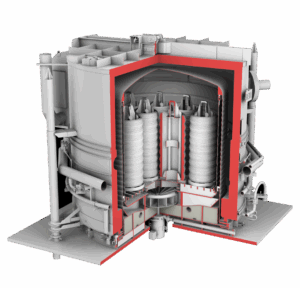

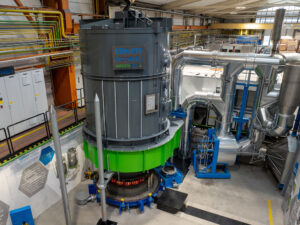

The GREENBAFx® product line was developed in response to customer demand for equipment that combines market competitiveness, regulatory compliance, and energy efficiency. Designed to meet strict environmental standards, including climate protection initiatives and air pollution regulations, the furnace significantly reduces energy consumption and emissions. With features such as an emission-free process, integrated electric heating, and advanced heat exchange between charge stacks, it achieves energy savings of up to 30 %. The system also minimizes crane movements and allows for compact layouts, while its modular components can be retrofitted for added flexibility. GREENBAFx® represents a forward-thinking solution that benefits both customers and the environment through innovation and sustainability.

The GREENBAFx® product line was developed in response to customer demand for equipment that combines market competitiveness, regulatory compliance, and energy efficiency. Designed to meet strict environmental standards, including climate protection initiatives and air pollution regulations, the furnace significantly reduces energy consumption and emissions. With features such as an emission-free process, integrated electric heating, and advanced heat exchange between charge stacks, it achieves energy savings of up to 30 %. The system also minimizes crane movements and allows for compact layouts, while its modular components can be retrofitted for added flexibility. GREENBAFx® represents a forward-thinking solution that benefits both customers and the environment through innovation and sustainability.

Learn more about our GREENBAFx® here.

CO2 reduction, NOx reduction, Energy savings

The EBNER Temperature Measurement System ensures precise, real-time temperature monitoring throughout the entire process, including the water quench phase, and complies with the AMS 2750 and CQI-9 standards. With a 6-channel data logging system, it enables better control of heating and cooling cycles, reducing soaking time, optimizing cooling, and lowering energy consumption. The design also supports reduced water flow, improved strip shape, and full verification of the heat treatment process. The rapid installation, adjustable system parameters and safe, regular facility surveys make it a reliable and efficient solution.

Learn more about our Temperature Measurement System.

Energy savings

Our optimized design for a furnace inlet provides an energy savings of over 20 % in comparison to conventional designs, significantly reducing carbon emissions and minimizing the impact of heat on surrounding areas. The flexible configuration of the inlet can be adapted to suit a wide variety of strip formats and can be easily installed in existing facilities, making it both efficient and future-proof.

Our optimized design for a furnace inlet provides an energy savings of over 20 % in comparison to conventional designs, significantly reducing carbon emissions and minimizing the impact of heat on surrounding areas. The flexible configuration of the inlet can be adapted to suit a wide variety of strip formats and can be easily installed in existing facilities, making it both efficient and future-proof.

CO2 reduction, Energy savings

To ensure that energy resources are used efficiently, one of our core sustainability goals is to continuously reduce and control heat losses at our industrial furnaces. In response to customer requests, we have focused on improving the insulation of the furnace walls by incorporating higher-quality materials and implementing more effective design approaches.

This improved insulation significantly reduces heat losses, by as much as 15 %. By improving thermal efficiency, we reduce operating costs and contribute to environmental sustainability by lowering the overall carbon footprint. These efforts align with our commitment to sustainable production and responsible energy usage, ensuring we fulfill both the expectations of our customers and global sustainability standards.

Energy savings

An EBNER hydrogen recycling system minimizes hydrogen losses by efficiently filtering and reusing it during the process. This approach enhances energy efficiency, reduces hydrogen consumption and contributes to the long-term reduction of operating costs..

An EBNER hydrogen recycling system minimizes hydrogen losses by efficiently filtering and reusing it during the process. This approach enhances energy efficiency, reduces hydrogen consumption and contributes to the long-term reduction of operating costs..

- Reduced consumption of H2 process atmosphere.

- Lower operating costs and rapid ROI.

- Hydrogen contaminated with lubricant is “flared off” at the outburner (the energy that is released is reused at the heating bell).

- Minimally-contaminated hydrogen (e.g., from the soaking phase) is stored and reused as a process atmosphere during the heating phase (in which lubricants evaporate) of the next process.

- At bell annealer facilities, hydrogen consumption can be reduced up to 30 % (depending on the operating mode).

- At continuous heat treatment facilities, hydrogen consumption can be reduced by up to 75 % – without influencing the quality of the strip surface.

Energy savings

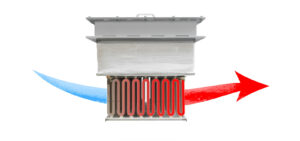

Waste heat recovery plays a key role in improving energy efficiency, as it recycles thermal energy from exhaust gases and cooling water. Internally, this recovered energy supports processes such as the preheating of strip, the heating of degreaser tanks and drying. Externally, it can be used to heat workshops, showers or meet other facility needs – reducing both overall energy consumption and environmental impact.

Waste heat recovery plays a key role in improving energy efficiency, as it recycles thermal energy from exhaust gases and cooling water. Internally, this recovered energy supports processes such as the preheating of strip, the heating of degreaser tanks and drying. Externally, it can be used to heat workshops, showers or meet other facility needs – reducing both overall energy consumption and environmental impact.

CO2 reduction, Energy savings

The EBNER Process Atmosphere Burn-out Burner uses combustion to collect energy from the process atmosphere, as it “flares off” flammable waste products. This energy is then returned directly to the process, for example to the heating bell of a bell annealer facility. This also has the effect of reducing air pollution, as vaporized lubricants combust.

Energy savings

Combustion air preheating significantly boosts energy efficiency and reduces CO₂ emissions. Central recuperators offer fuel savings of up to 20 % in applications like austenitizing furnaces, while radiant tubes with recuperative burners achieve savings of up to 30 %. In comparison with conventional systems, large recuperators can reduce fuel consumption and carbon emissions by 7 % at bell annealer facilities.

CO2 reduction, Energy savings

In response to rising energy costs and the push for digitalization, EBNER developed the ATMOSPHEREperfect software module for HICON/H₂® bell annealers. This intelligent system uses real-time data and advanced algorithms to automatically regulate hydrogen flow, reducing energy and hydrogen consumption by up to 20 % without compromising product quality. Integrated into the VISUALFURNACES platform, it enhances process stability, supports decarbonization, and strengthens the steel industry’s competitiveness through digital transformation and sustainability.

Energy savings

ECOMODE and TREATperfect are advanced tools designed to reduce energy consumption in heat treatment. ECOMODE optimizes fan and blower speeds and adjusts annealing times for maximum efficiency. TREATperfect enhances this with intelligent, real-time control and predictive planning, minimizing energy use, emissions, and material waste. Together, they improve furnace performance, increase throughput, and support sustainable, cost-effective manufacturing—even in retrofitted systems.

Energy savings

Environment

The ECOBURN FL flameless burner ensures stable combustion without a visible flame, using exhaust gas recirculation to achieve uniform temperature distribution. This advanced design reduces NOx emissions by up to 60 % compared to conventional flame burners, making it a highly efficient and environmentally-friendly solution.

Learn more about our burner systems here.

NOx reduction

Waste heat recovery plays a key role in improving energy efficiency, as it recycles thermal energy from exhaust gases and cooling water. Internally, this recovered energy supports processes such as the preheating of strip, the heating of degreaser tanks and drying. Externally, it can be used to heat workshops, showers or meet other facility needs – reducing both overall energy consumption and environmental impact.

Waste heat recovery plays a key role in improving energy efficiency, as it recycles thermal energy from exhaust gases and cooling water. Internally, this recovered energy supports processes such as the preheating of strip, the heating of degreaser tanks and drying. Externally, it can be used to heat workshops, showers or meet other facility needs – reducing both overall energy consumption and environmental impact.

CO2 reduction, Energy savings

By reducing the concentration of O₂ in the combustion air, an EBNER exhaust gas return system can reduce NOx emissions by up to 25 %.

NOx reduction

The ECOBURN H2 FLEX offers the greatest possible degree of flexibility, as it can be operated with natural gas, hydrogen or any desired mixture of the two. It supports combustion air preheating up to 550 °C, and is designed to allow external exhaust gas admixing. With UV flame supervision, an infinitely variable output range of 60 – 175 kW per burner and an optional flameless mode, this burner provides high efficiency, low emissions and reliable performance in a wide variety of applications.

CO2 reduction

Electrification is a critical driver in the transition toward sustainable industrial processes. It offers a significant reduction in emissions, which is essential in addressing climate change and meeting global decarbonization goals. By replacing gas-fired burners with electric solutions, industries can achieve alignment with environmental regulations.

Electrification is a critical driver in the transition toward sustainable industrial processes. It offers a significant reduction in emissions, which is essential in addressing climate change and meeting global decarbonization goals. By replacing gas-fired burners with electric solutions, industries can achieve alignment with environmental regulations.

- Can be retrofitted into existing gas-fired systems

- Applicable for various furnaces with low to high-temperature applications

- Electric radiant tubes

- Resistance heating systems

- Induction Heating systems

- Hybrid heating system

CO2 and NOx reduction

Our optimized design for a furnace inlet provides an energy savings of over 20 % in comparison to conventional designs, significantly reducing carbon emissions and minimizing the impact of heat on surrounding areas. The flexible configuration of the inlet can be adapted to suit a wide variety of strip formats and can be easily installed in existing facilities, making it both efficient and future-proof.

Our optimized design for a furnace inlet provides an energy savings of over 20 % in comparison to conventional designs, significantly reducing carbon emissions and minimizing the impact of heat on surrounding areas. The flexible configuration of the inlet can be adapted to suit a wide variety of strip formats and can be easily installed in existing facilities, making it both efficient and future-proof.

CO2 reduction, Energy savings

![]() HICON/H2Q quenching technology replaces traditional molten metal quenching methods in hardening and tempering lines, eliminating the use of lead and its associated emissions. The results in a bright, lead-free strip surface with improved product quality. Downstream processes like grinding or polishing can often be avoided, and working conditions for strip cleaning personnel are significantly improved.

HICON/H2Q quenching technology replaces traditional molten metal quenching methods in hardening and tempering lines, eliminating the use of lead and its associated emissions. The results in a bright, lead-free strip surface with improved product quality. Downstream processes like grinding or polishing can often be avoided, and working conditions for strip cleaning personnel are significantly improved.

Pb reduction

The SCR (Selective Catalytic Reduction) system is designed to significantly reduce NOx emissions in furnace operations.

- NOx reduction with SCR system at the exhaust gas stack

- Catalyzer unit for chemical reaction and NOx reduction

- Continuous monitoring of exhaust gas emissions

- Meets strict emission standards

- Possibility to upgrade existing facilities

- Several successful installations

NOx reduction

EBNER strip cleaning systems can be operated either without or with a minimal amount of lye. The primary cleaning agent is hot water under high pressure, and in many cases the use of lye can either be minimized (e.g. used only in specific cleaning zones like the brush cleaning zone) or even eliminated entirely.

EBNER strip cleaning systems can be operated either without or with a minimal amount of lye. The primary cleaning agent is hot water under high pressure, and in many cases the use of lye can either be minimized (e.g. used only in specific cleaning zones like the brush cleaning zone) or even eliminated entirely.

Learn more about our Strip Cleaning Facilites.

NaOH reduction, KOH reduction

The GREENBAFx® product line was developed in response to customer demand for equipment that combines market competitiveness, regulatory compliance, and energy efficiency. Designed to meet strict environmental standards, including climate protection initiatives and air pollution regulations, the furnace significantly reduces energy consumption and emissions. With features such as an emission-free process, integrated electric heating, and advanced heat exchange between charge stacks, it achieves energy savings of up to 30 %. The system also minimizes crane movements and allows for compact layouts, while its modular components can be retrofitted for added flexibility. GREENBAFx® represents a forward-thinking solution that benefits both customers and the environment through innovation and sustainability.

The GREENBAFx® product line was developed in response to customer demand for equipment that combines market competitiveness, regulatory compliance, and energy efficiency. Designed to meet strict environmental standards, including climate protection initiatives and air pollution regulations, the furnace significantly reduces energy consumption and emissions. With features such as an emission-free process, integrated electric heating, and advanced heat exchange between charge stacks, it achieves energy savings of up to 30 %. The system also minimizes crane movements and allows for compact layouts, while its modular components can be retrofitted for added flexibility. GREENBAFx® represents a forward-thinking solution that benefits both customers and the environment through innovation and sustainability.

Learn more about our GREENBAFx® here.

CO2 reduction, NOx reduction, Energy savings

Combustion air preheating significantly boosts energy efficiency and reduces CO₂ emissions. Central recuperators can save up to 20 % fuel in applications like austenitizing furnaces, while radiant tubes with recuperative burners achieve savings of up to 30 %. In bell annealing furnaces, large recuperators offer an additional 7 % fuel and CO₂ reduction compared to standard systems.

CO2 reduction, Energy savings