Save Costs with Our H₂ Recycling System Upgrade for Bright Annealing Lines

Get your free, non-binding consultation now!

If your bright annealing line is facing high hydrogen consumption costs, we have the solution for you:

The fully integrated EBNER H2-Recyling System!

In bright annealing lines for stainless steels or copper alloys, process atmospheres with high hydrogen content (up to 100 % H2) are typically used to ensure oxide-free strip surfaces during heat treatment.

However, hydrogen consumption represents a significant operational cost factor (OPEX).

With continuously rising energy and gas prices, optimizing operating costs has become more important than ever.

A hydrogen process gas recycling system offers the ideal solution.

This system significantly reduces hydrogen consumption during annealing.

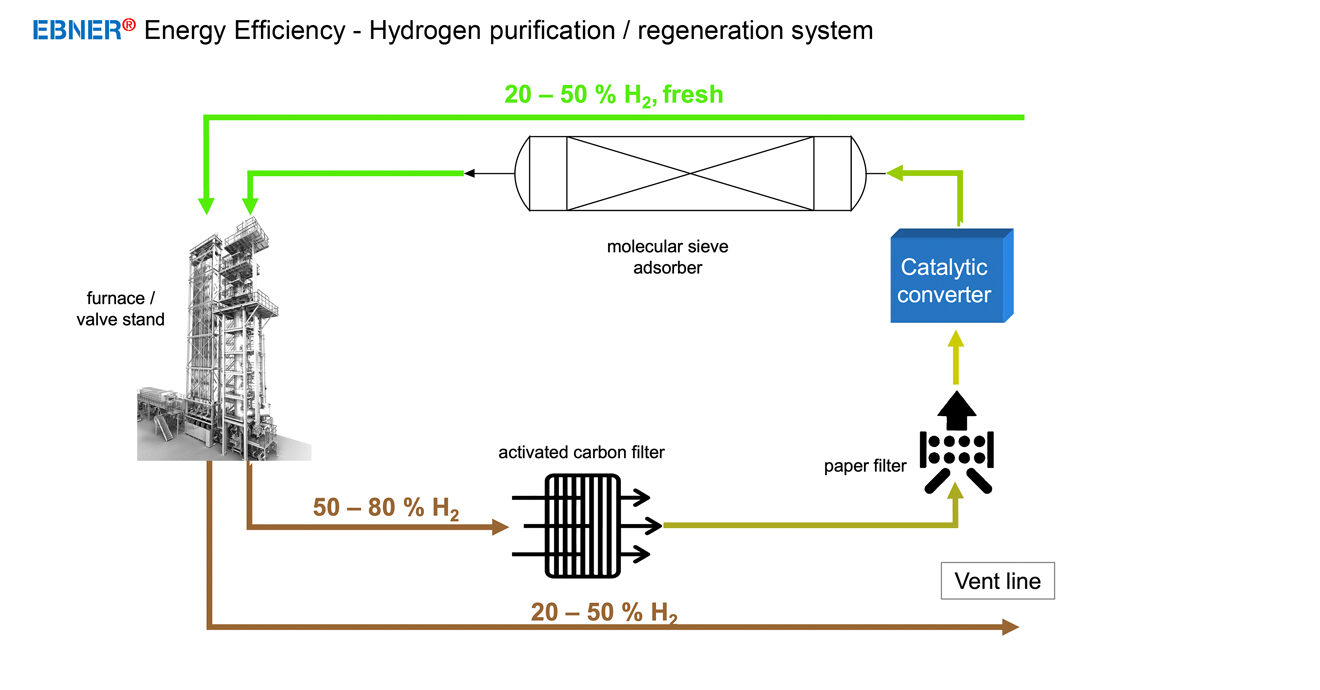

The contaminated hydrogen process gas—containing moisture, rolling oil vapors, and other impurities—is extracted at the furnace inlet and passed through a multi-stage gas cleaning system consisting of an activated carbon filter, additional filter, oxygen remover, and molecular sieve purification unit. After treatment, the cleaned gas is returned to the annealing system.

With the fully integrated EBNER H2 Recycling System, recycling rates of up to 80 % can be achieved today—without compromising strip surface quality or system safety.

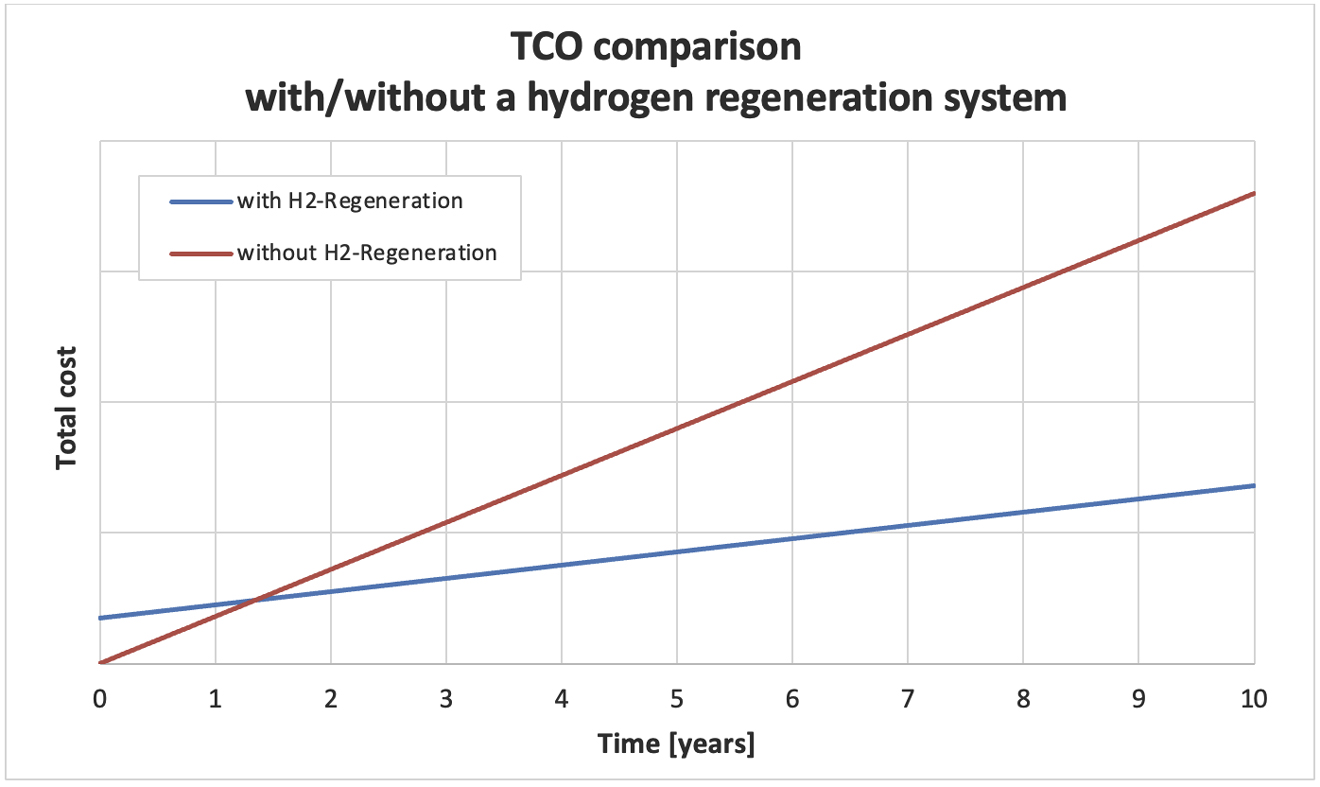

Typical payback periods range from 1 to 3 years, depending on plant capacity and current media costs.

For example, for a plant with an annual annealing capacity of 40,000 tons and hydrogen costs of € 0.90/m³, the Total Cost of Ownership (TCO) comparison is as follows: